Building the circular economy

The Australia and New Zealand Recycling Platform (ANZRP) has established a partnership with the CRDC Circular Solutions (Australia) to improve the circularity of plastic recovered from e-waste recycling.

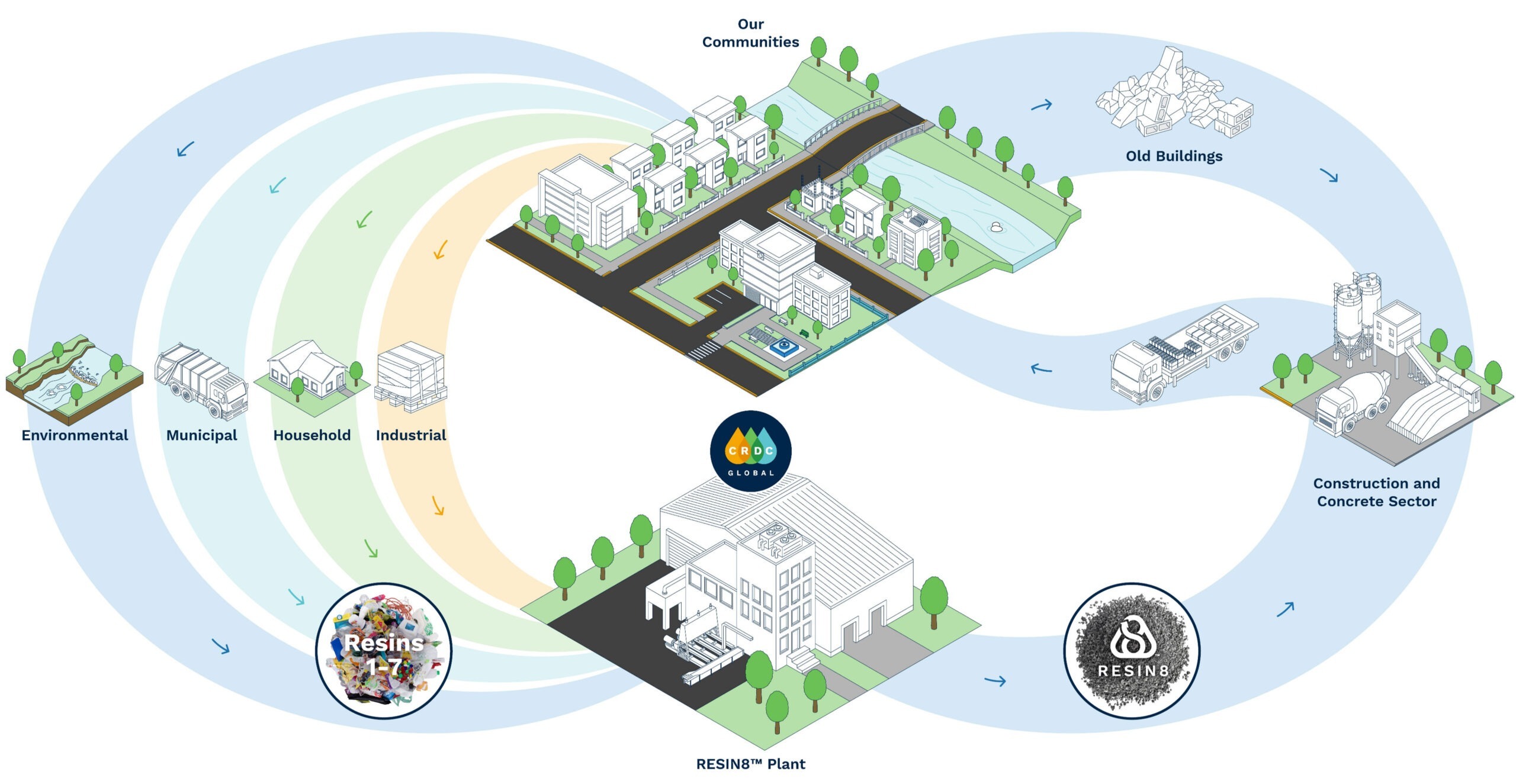

The purpose of CRDC is to create value from the world’s (hard to recycle) plastic waste and was born out of a powerful idea – to fully harness the potential of regenerative design.

The joint venture, CRDC Victoria, has built a plant in Melbourne using the RESIN8TM; manufacturing process – the fourth facility of its kind globally and the first in the Asia-Pacific region.

Approximately 25% of the material used to make TVs, computer equipment and printers is plastic, which can be difficult to recycle and may end up in landfill.

ANZRP collects about 5,000 tonnes per year of plastic from e-waste. CRDC Victoria is now successfully using some of this plastic resource to produce RESIN8.

Watch the corporate video about creating value from the world’s plastic waste

What is the RESIN8 CircularPledge Program?

- A program that enables plastic waste generators to take responsibility for their plastic waste.

- A simple way for companies to demonstrate their commitment to a circular economy.

- An opportunity to deliver both environmental and social outcomes by supporting community projects.

How does the RESIN8 CircularPledge Program Work?

- Companies purchase an amount of RESIN8 that ensures a chosen weight of plastic is turned into RESIN8 and used in a project.

- Companies can also provide waste plastic to be recycled.

- The purchased RESIN8 is donated for use in an approved community project – delivering environmental and social outcomes.

- All parties collectively promote the community project and their support.

- Independent auditing provides assurance of the outcome.

Community Projects

A range of potential projects and partners will be identified so that participants can choose where their donation is sent.

Our first confirmed partners are Habitat for Humanity and Fareshare.

FareShare is a food rescue organisation that operates Australia’s largest charity kitchens. Its mission is to mobilise volunteers to cook delicious, free meals from rescued, donated and homegrown ingredients to improve the lives of Australians

in hardship.

Habitat for Humanity Victoria (HFHV) is part of a global organisation, working in more than 70 countries worldwide towards its vision of a world where everyone has a decent place to live.

Cost of Participation

The cost to participate in the RESIN8 CircularPledge Program is $1.50/kg of RESIN8 purchased ($1500/t).

1t of plastic comes from:

- ~400 desktop printers

- ~900 plastic storage tubs (50 litre)

- ~1600 plastic buckets

- ~2000 laptops

- ~125,000 chip packets

- ~150,000 plastic shopping bags

- ~300,000 take away coffee cup lids

What is RESIN8 and what are its applications

RESIN8 is a high performing and versatile mineral polymer that can be used in a variety of concrete and asphalt applications.

Its uses include:

As a lightweight, or insulation enhancing functional aggregate replacement in blocks

As an additive to increase stiffness in hot-mix-asphalt

To increase yield by acting as an insulative aggregate replacement in bag mixed concrete

Common product applications for RESIN8 include use in:

- pavers

- pre-cast concrete products

- additive to ready-mix concrete

- concrete blocks

RESIN8 is a construction material that harvests the beneficial properties of a problematic waste stream and utilises this to produce a new value-added material input that can be readily used in new building products.

RESIN8’s economic and environmental credentials

Benefits of RESIN8 include:

- provides 2.7 times the level of thermal insulation when compared to conventional alternatives.

- improves overall acoustics.

- is 3.6 times lighter than alternatives, which makes it more economical to transport.

- lowers water absorption.

- maintains strength during the product life span.

- fire resistant.

When used in asphalt applications RESIN8 also:

- increases the hot-mix stiffness without jeopardising its fatigue strength; and

- improves the mechanical properties of the mix.

RESIN8 is a carbon negative material which assists the building industry to reduce the embodied carbon in construction and infrastructure projects.

The RESIN8 process converts plastic into a mineral-polymer and from hydrophobic to hydrophilic. This means the aggregate bonds well with cement, unlike other pure plastic additives.

The product meets industry standards for compression, strength, gradation and fire resistance. All products produced using RESIN8 are recyclable at end-of-life – offering a truly exciting circular economy story.

RESIN8 in use around the world

RESIN8 is tried and proven and is now being used on several continents and numerous countries such as the USA, Australia, Mexico, Costa Rica, and South Africa for a wide range of applications and projects, such as:

- as building blocks for affordable housing.

- high end infrastructure.

- blocks and pavers in construction projects.

- barriers.

- asphalt mixes.

- residential kerbs and channels.

Barriers

Costa Rica

Asphalt

Mexico, Costa Rica

Affordable Housing

Costa Rica, South Africa

Blocks and Pavers

USA, Mexico, Costa Rica, South Africa

High End Infrastructure

USA (Braskem)

Residential Curbs and Channels

South Africa

Which plastics can CRDC Victoria accept?

The RESIN8 process accepts plastic resins 1 to 7 and in both soft and rigid forms. It is also able to take commingled waste plastic and multilayered polymers. Input sources are summarised in the table below:

| Resin | Resin Type | Common Application |

| 1 | Polyethylene terephthalate (PET) | Soft drink and water bottles, microwave food trays, mouthwash |

| 2 | High-density polyethylene (HDPE) | Laundry detergent bottles, milk, water, juice bottles |

| 3 | Polyvinyl chloride (PVC) | Bottles for shampoo, cleaning, cooking oil, clamshell food containers, plastic wrap |

| 4 | Low-density polyethylene (LDPE) | Squeezable bottles, bread bags, frozen food bags, plastic bags and packaging waste from IT equipment |

| 5 | Polypropylene (PP) | Medicine bottles, yoghurt containers, bottle caps, margarine tubs |

| 6 | Polystyrene (PS) | Food trays, cups, egg containers, carry-out containers, packaging waste from IT equipment |

| 7 | Other – including ABS/ HIPS from e-waste | Reusable water bottles, CD cases, sunglasses |

Delivering triple bottom line outcomes

The CRDC Victoria joint venture established by ANZRP and CRDC Circular Solutions (Australia) is also proving to be valuable beyond the production of new products.

CRDC Victoria has created 7 full time equivalent (FTE) jobs and will initially process up to 6,000 tonnes of waste plastic per year into new products. The facility, which was funded through investment by the JV partners and a grant of $500,000 from Sustainability Victoria, was opened by the Victorian Minister for the Environment, Steve Dimopoulos on the 29th of April 2024.

Click here to read more about the launch.

Click here to Download the RESIN8 CircularPledge Brochure.