-

ANZRP staff “Wear it Yellow” for National Reconciliation Week

2025-06-13 -

ANZRP & PonyUp for Good visit ACE Recycling

2025-06-13 -

Industry News – Connections June Newsletter 2025

2025-06-13 -

ANZRP Recertified as a Great Place to Work® in 2025

2025-05-29 -

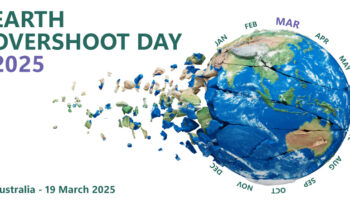

Australia Oversteps the Mark

2025-03-26 -

TechCollect NZ extends its services by providing support to Pacific Island nations

2025-03-05 -

Australia and New Zealand Recycling Platform (ANZRP) Announces New Chair and Two New Board Members Over the Past Three Months

2025-02-18 -

Carla Vasconi Appointed Chief Executive Officer (CEO) of Australia and New Zealand Recycling Platform (ANZRP)

2025-02-12 -

Productivity Commission: Opportunities for Creating a Circular Economy

2024-11-28 -

Do we still have a blind spot when it comes to e-waste?

2024-11-08 -

Australian Packaging Covenant Organisation 2030 strategic plan – a shift in thinking and approach

2024-09-03 -

ANZRP unlocks the plastic recycling puzzle

2024-08-29